TOKYO / AUCKLAND: In a breakthrough collaboration that signals the next era of electric propulsion and high-performance satellite manoeuvrability, Japan’s Faraday Factory Japan LLC and New Zealand’s Zenno Astronautics have announced a strategic partnership to develop advanced high-temperature superconducting (HTS) magnets specifically tailored for space use.

Faraday Factory, recognized globally as the leading manufacturer of superconducting tape, and Zenno Astronautics, an emerging innovator in spaceflight electromagnetics, have joined forces to expand the boundaries of superconductor performance in orbit. The partnership brings together decades of Japanese materials science with Zenno’s revolutionary vision for fuel-free satellite control systems.

Pioneering Superconductivity in Space

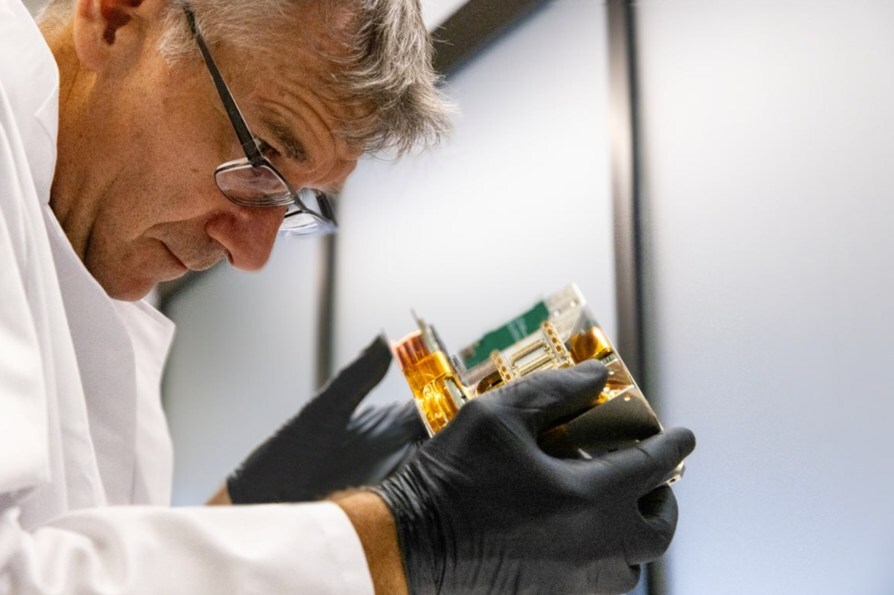

Faraday Factory has drawn on more than 30 years of expertise in high-temperature superconductors to refine materials able to perform in the harsh environment of space. Under this agreement, the company will supply Zenno with new generations of HTS tapes — including its recently unveiled Mirai superconducting tape, launched earlier this year — for integration into Zenno’s magnetic systems.

By reengineering conductors to operate efficiently under variable temperatures and magnetic loads encountered in orbit, the collaboration aims to deliver superconducting magnets that operate with exceptional performance, increased thermal margin, reduced energy usage, and lighter weight. These improvements are particularly crucial for modern spacecraft systems, where efficiency and compactness are the cornerstones of mission success.

According to Sergey Samoilenkov, Director of Strategy at Faraday Factory Japan, progress in materials engineering will determine the speed of innovation in superconducting space technologies. “Our work demonstrates that high-temperature superconducting devices can achieve dramatically higher performance when guided by materials science optimization,” he said. “This collaboration unites expertise across both organizations to create tangible, next-generation results for the space industry.”

Shaping the Future of Satellite Control

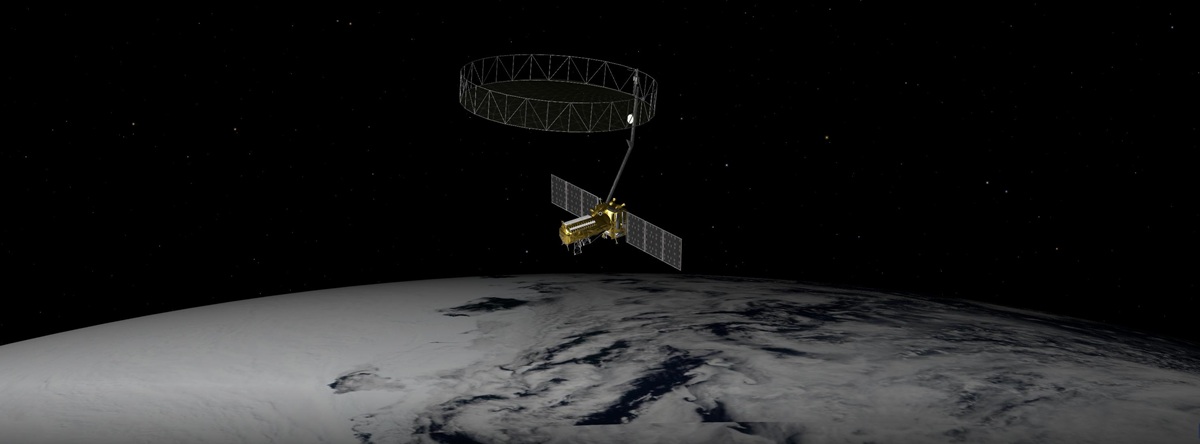

The partnership will focus its early developments on the operational ranges of Zenno’s flagship platform, the Z01 Supertorquer—an electromagnetic system designed to control satellite orientation and motion without traditional fuel-based thrusters. The resulting HTS technology is expected to enhance spacecraft manoeuvrability while significantly cutting power consumption and system weight.

Zenno’s co-founder and Chief Product Officer, Sebastian Wieczorek, described the Mirai tape as potentially “transformative” for the company’s existing architecture. “Mirai can materially enhance the Supertorquer’s performance by enabling faster response times and stronger magnetic fields within the same compact form factor,” he said. “For future satellites, that means unmatched control and greater freedom to operate efficiently in orbit.”

Such advancements could revolutionize how satellites maintain and modify their positions, with applications extending into autonomous swarm operations, precision docking, and sustainable long-duration missions.

From Power Grids to Orbit

Faraday Factory’s Mirai tape already serves markets such as clean fusion energy and next-generation power grids. Adapting the same underlying technology for space introduces both novel engineering challenges and opportunities for efficiency gains that could ripple across the global aerospace sector.

Faraday Factory’s manufacturing capability—the largest in the world for HTS tapes—positions it to meet accelerating demand from multiple industries. The company uses proprietary pulsed laser deposition techniques to achieve high-quality films that maintain conductivity even under extreme conditions.

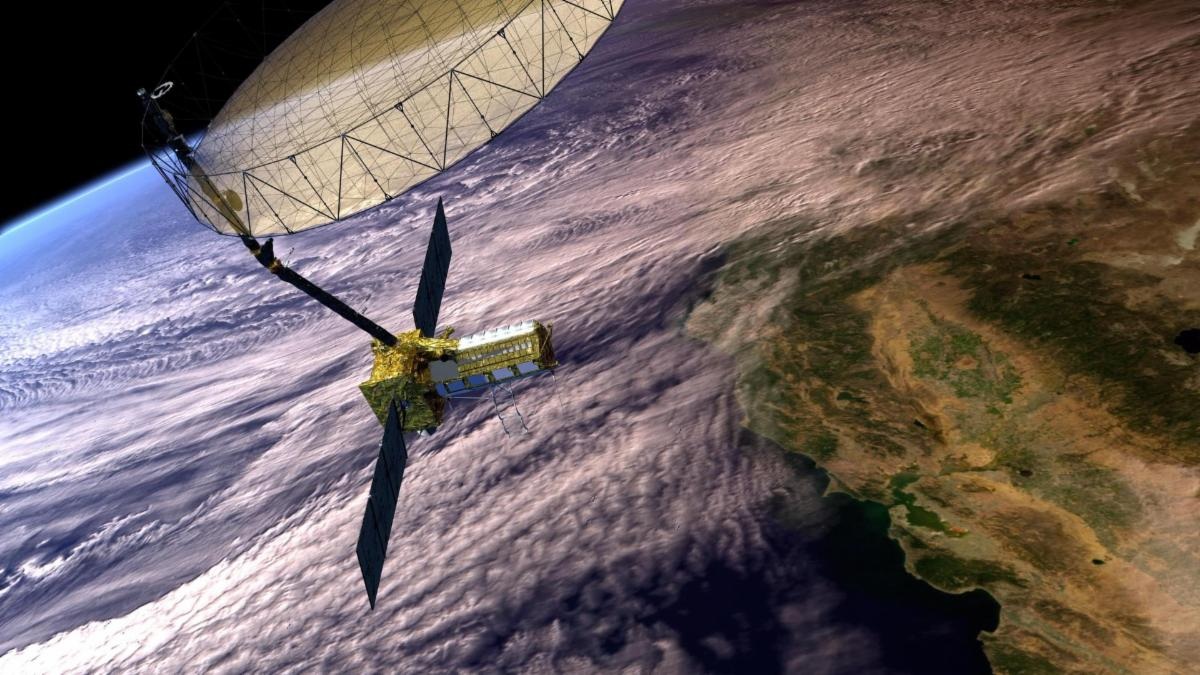

Zenno Astronautics, meanwhile, continues to expand its presence across New Zealand, Europe, and the United States as it develops superconducting structures for sustainable and safe spacecraft operations. Its portfolio already includes fuel-free control systems, shielding technologies to protect against radiation, and magnetic plasma manipulation tools designed to increase longevity and autonomy in satellites.

A New Impulse for Space Innovation

Industry observers note that integrating advanced HTS systems into commercial and scientific spacecraft could redefine propulsion and power control strategies. By combining Faraday Factory’s precision in superconducting materials with Zenno’s system-level ingenuity, this partnership delivers a glimpse of a near future where spacecraft are more environmentally sustainable and mechanically precise.

The first generation of co-developed HTS materials is projected to enter testing phases within 2026, with orbital demonstrations anticipated soon after. Should the collaboration meet its objectives, it could establish a new benchmark for space magnetics — and solidify Japan and New Zealand’s leadership in the emerging field of superconducting space technologies.