Englewood, Colorado: XTI Aerospace, Inc., a leading innovator in the xVTOL and powered-lift aircraft sector, announced today the successful completion of a critical propulsion technical familiarization (“Tech Fam”) meeting with the Federal Aviation Administration (FAA). This milestone marks a significant advancement in the certification process of XTI’s groundbreaking TriFan 600, a vertical takeoff and landing (VTOL) fixed-wing aircraft designed to revolutionize business aviation.

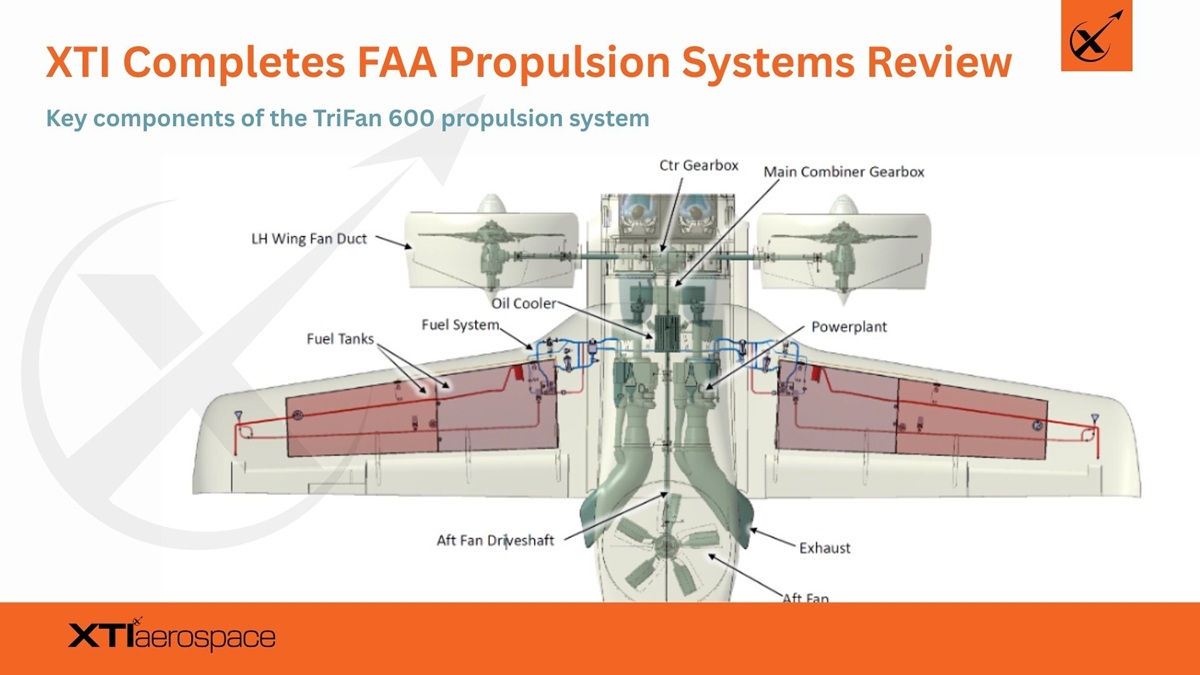

The propulsion Tech Fam meeting involved detailed technical discussions between engineering experts from XTI Aircraft Company, a subsidiary of XTI Aerospace, and FAA officials. The comprehensive review focused on the TriFan 600’s propulsion system, including engines, drive train, fuel system, propellers, engine compartments, and structural mounts supporting the drive train. This collaborative session was pivotal in assessing compliance with stringent FAA certification requirements.

The meeting addressed critical certification topics such as:

- Engine fire containment: Ensuring the propulsion system can safely contain and manage fire incidents.

- Bird strike impact resistance: Evaluating the aircraft’s ability to withstand bird strikes without compromising safety.

- Cabin occupant safety: Protecting passengers through robust design of propulsion and structural systems.

- Fuel management systems: Verifying reliable and safe fuel delivery and monitoring.

- Instrumentation and sensor integration: Implementing advanced sensors to detect system anomalies and support proactive maintenance.

David Ambrose, Vice President of Engineering at XTI Aerospace, emphasized the importance of the FAA dialogue, “As XTI completes this latest Tech Fam meeting with the FAA, our engineering team continues its collaborative approach to the type certification of the TriFan 600. The FAA’s insights during these meetings provide valuable guidance on our systems and structural design strategies, reinforcing our commitment to delivering a safe and reliable aircraft.”

The TriFan 600 is poised to create a new category in aviation known as xVTOL, combining the vertical takeoff and landing capabilities of a helicopter with the speed and range of a fixed-wing business aircraft. Key performance highlights include:

- Vertical Takeoff and Landing (VTOL): Enabling operations from confined spaces without the need for traditional runways.

- Cruising speeds exceeding 300 mph: Offering rapid point-to-point travel for business and personal use.

- Range up to 1,000 miles: Connecting cities and regions with non-stop flights, enhancing operational flexibility.

This innovative aircraft addresses growing market demands for faster, more efficient, and environmentally responsible air travel options. The TriFan 600’s certification progress, bolstered by milestones such as the propulsion Tech Fam review, brings XTI closer to commercial production and delivery.

XTI Aerospace’s open and transparent engagement with the FAA exemplifies its dedication to meeting rigorous safety and performance standards. The Tech Fam meetings serve as a platform for early-stage technical alignment, reducing certification risks and accelerating the timeline toward final approval.

This collaborative process not only ensures compliance with regulatory requirements but also integrates FAA feedback into design refinements, enhancing overall aircraft safety and reliability. XTI’s proactive approach is a model for innovative aerospace companies navigating complex certification landscapes.

XTI Aerospace is headquartered near Denver, Colorado, and is the parent company of XTI Aircraft Company. The company is pioneering the development of the TriFan 600, a fixed-wing business aircraft with VTOL capabilities, designed to redefine the standards of speed, range, and operational flexibility in the aviation industry.

In addition to its aerospace innovations, XTI Aerospace operates the Inpixon business unit, a global leader in real-time location systems (RTLS) technology. Inpixon’s location intelligence solutions are widely used in industrial environments worldwide to optimize operations, boost productivity, and enhance safety.